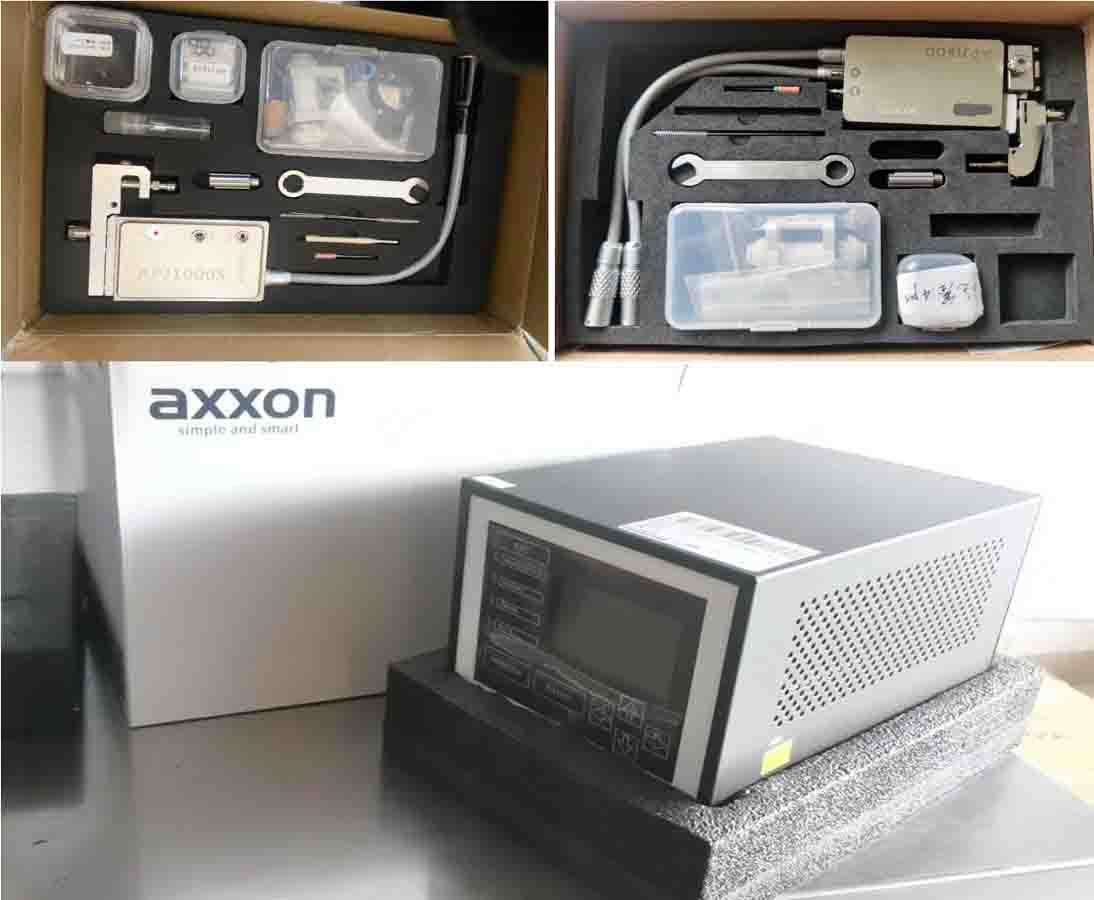

AXXON Dispensing Valve Parts - Nozzles, Tappets, and Accessories

AXXON dispensing valve parts are engineered for precision and reliability in industrial applications. Our range includes nozzles, tappets, and accessories compatible with APJ series (APJ1500, APJ2000, APJ3000, APJ5000) and V series (V-6500D, V-7500) dispensing valves. Essential for industries like electronics, automotive, and manufacturing, these components ensure accurate and consistent fluid dispensing.

Featured products: AXXON 0.1 nozzle APJ1006-9 MMG18007401 and 1.5 mm ceramic firing pin APJ1021-3-2 MMG18009901.

Note: This page showcases a selection of our extensive range. For custom dispensing valve parts, contact our team.

Ⅰ、Compatible Brands for Nozzles and Tappets

AXXON parts integrate seamlessly with systems from brands like Axxon, Nordson EFD, VERMES, Techcon Systems, Graco, GKG, ANDA, Mingseal, GK-PRETECH, Asymtek, Fisnar, Musashi Engineering, Precision Valve & Automation, GPD Global, and various Chinese dispenser brands.

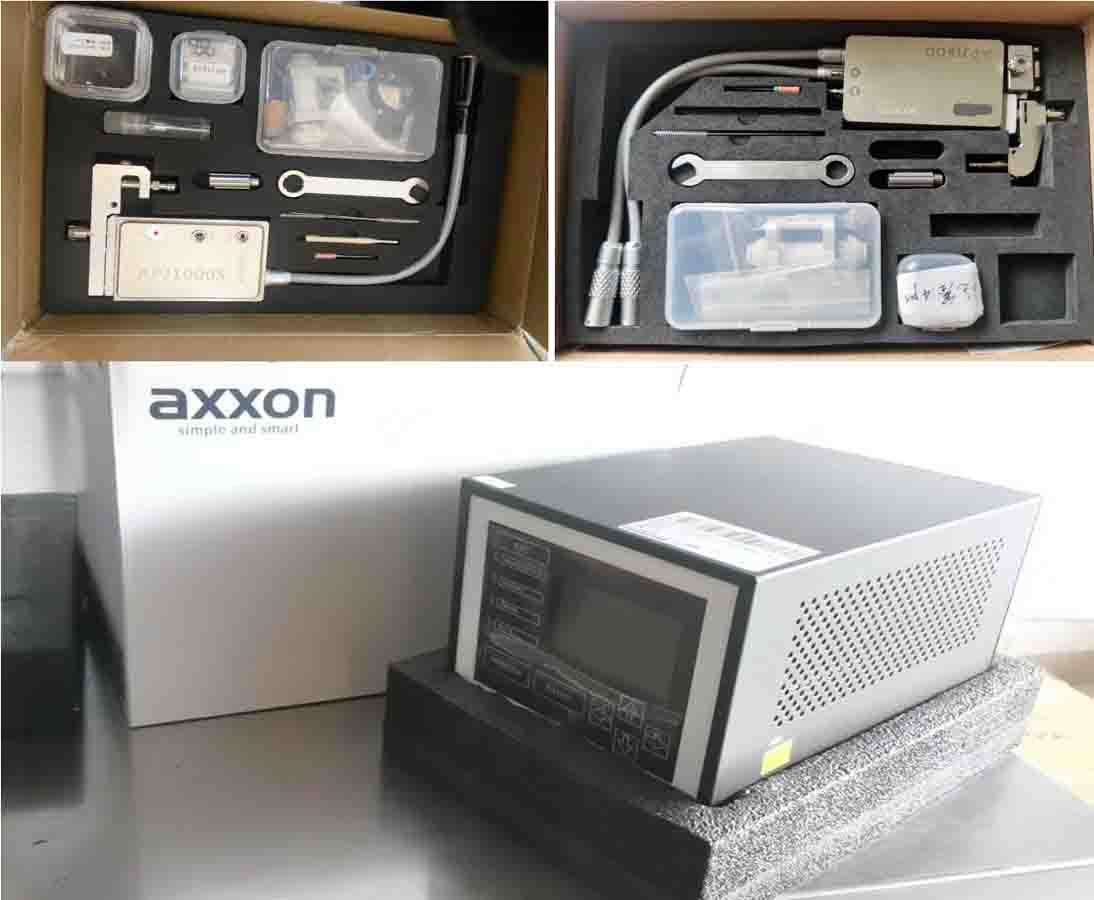

Explore the full AXXON dispensing valve set:

Ⅱ、AXXON Dispensing Valve Part Numbers

Nozzles

-

AXXON MMG18005601 APJ1006-2 nozzle 75um

-

AXXON MMG18050701 APJ1006-1-2 nozzle 50um-1.2

-

AXXON MMG18005701 APJ1006-3 nozzle 100um

-

AXXON MMG18010801 APJ1006-3-1 Ceramic Nozzle 100um

-

AXXON MMG18025901 APJ1006-3-2 Nozzle 100um (C)

-

AXXON MMG18007401 APJ1006-9 Nozzle 100um-2.5

-

AXXON MMG18053301 APJ1006-9-1 Nozzle 100um-1.6

-

AXXON MMG18012201 APJ1006-15 Nozzle 100um-3.5

-

AXXON MMG18016301 APJ1006-17-1 Nozzle 100um-4.5 Extended Nozzle

-

AXXON MMG18007701 APJ1006-12 Nozzle 100um-5 (J)

-

AXXON MMG18016701 APJ1006-12-1 Nozzle 100um-5 (S)

-

AXXON MMG18049901 APJ1006-12-2 Nozzle 100um-6

-

AXXON MMG18007201 APJ1006-7 Nozzle 125um

-

AXXON MMG18010901 APJ1006-7-1 Ceramic Nozzle 125um

-

AXXON MMG18007501 APJ1006-10 Nozzle 125um-2.5

-

AXXON MMG18019501 APJ1006-10-1 Nozzle 125um-4.5

-

AXXON MMG18007301 APJ1006-8 Nozzle 150um

-

AXXON MMG18011001 APJ1006-8-1 Ceramic Nozzle 150um

-

AXXON MMG18026101 APJ1006-8-2 Nozzle 150um (C)

-

AXXON MMG18009201 APJ1006-13 Nozzle 150um-2.5

-

AXXON MMG18019601 APJ1006-13-1 Nozzle 150um-4.5

-

AXXON MMG18031101 APJ1006-13-2 Nozzle 150um-5 (thin diameter)

-

AXXON MMG18051801 APJ1006-13-3 Nozzle 150um-5

-

AXXON MMG18005801 APJ1006-4 Nozzle 200um

-

AXXON MMG18026001 APJ1006-4-1 Nozzle 200um (C)

-

AXXON MMG18022701 APJ1006-11-1 Nozzle 200um-3.5

-

AXXON MMG18029701 APJ1006-11-5 Nozzle 200um-2.5

-

AXXON MMG18007601 APJ1006-11 Nozzle 200um-5

-

AXXON MMG18029601 APJ1006-11-4 Nozzle 200um-20

-

AXXON MMG18053401 APJ1006-11-6 Nozzle 200um-7 (1)

-

AXXON MMG18053501 APJ1006-11-7 Nozzle 200um-7 (2)

-

AXXON MMG18053601 APJ1006-11-8 Nozzle 200um-7 (3)

-

AXXON MMG18053701 APJ1006-11-9 Nozzle 200um-7 (4)

-

AXXON MMG18031501 APJ1006-19 Nozzle 250um

-

AXXON MMG18005901 APJ1006-5 Nozzle 300um

-

AXXON MMG18050801 APJ1006-5-2 Nozzle 300um-3.5

-

AXXON MMG18065301 APJ1006-5-4 Nozzle 300um-4.5

-

AXXON MMG18065901 APJ1006-5-6 Nozzle 350um-3.5 (JV)

-

AXXON MMG18006001 APJ1006-6 Nozzle 400um

-

AXXON MMG18031001 APJ1006-6-1 Ceramic Nozzle 400um

-

AXXON MMG18050901 APJ1006-6-2 Nozzle 400um-3.5

-

AXXON MMG18052601 APJ1006-6-3 Nozzle 500um-3.5

-

AXXON MMG18052701 APJ1006-6-4 Nozzle 500um-3.5 (J)

-

AXXON MMG18012701 APJ1006-16 Nozzle 600um

-

AXXON MMG18052801 APJ1006-6-5 Nozzle 600um-3.5

-

AXXON MMG18052901 APJ1006-6-6 Nozzle 600um-3.5 (J)

Tappets

-

AXXON MMG18005101 APJ1021-1 0.75mm dedicated Tappets

-

AXXON MMG18010201 APJ1021-1-2 0.75mm ceramic Tappets

-

AXXON MMG18010301 APJ1021-1-3 0.75mm gem Tappets

-

AXXON MMG18005201 APJ1021-2 1.0mm dedicated Tappets

-

AXXON MMG18010501 APJ1021-2-2 1.0mm ceramic Tappets

-

AXXON MMG18010601 APJ1021-2-3 1.0mm gem Tappets

-

AXXON MMG18014501 APJ1021-6 1.0mm extended ceramic Tappets

-

AXXON MMG18029001 APJ1021-6-1 1.0mm extended Tappets (GW)

-

AXXON MMG18016501 APJ1021-8 1.25mm extended ceramic Tappets

-

AXXON MMG18013501 APJ1021-5 1.25mm special Tappets

-

AXXON MMG18016201 APJ1021-7 1.5mm extended ceramic Tappets

-

AXXON MMG18005301 APJ1021-3 1.5mm special Tappets

-

AXXON MMG18009901 APJ1021-3-2 1.5mm ceramic Tappets

-

AXXON MMG18010001 APJ1021-3-3 1.5mm gem Tappets

-

AXXON MMG18025201 APJ1021-3-4 1.5mm Tappets extension 11 (ASF)

-

AXXON MMG18005401 APJ1021-4 2.0mm special Tappets

-

AXXON MMG18011201 APJ1021-4-2 2.0mm ceramic Tappets

-

AXXON MMG18011301 APJ1021-4-3 2.0mm gem Tappets

-

AXXON MMG18025301 APJ1021-4-5 2.0mm Tappets extension 11 (ASF)

-

AXXON MMG18023201 APJ1021-9 3.0mm special Tappets

-

AXXON MMG18052401 APJ1021-9-1 3.5mm special Tappets

-

AXXON MMG18052501 APJ1021-9-2 4.0mm special Tappets

Other Components

-

AXXON MMG18056901 APJ5003 piezoelectric valve body (without flow channel)

-

AXXON MMG18057001 APJ5001-1 valve body housing

-

AXXON MMG18070101 APJ5002 clamping module-1500

-

AXXON MMG18057101 APJ5004 1500 syringe holder

-

AXXON MMG18057201 APJ5019 APJ1500 syringe adapter

-

AXXON MMG18031201 APJ1043-1 star-shaped hand screw M5*12

-

AXXON MMG18057301 APJ5012 screw

-

AXXON MMG18004101 APJ1007 spring

-

AXXON MMG18057401 APJ5005 1500 support rod (metal)

-

AXXON MMG18057501 APJ5005-1 1500 wide mouth support rod (2.2)

-

AXXON MMG18057601 APJ5005-2 1500 short support rod

-

AXXON MMG18006201 APJ1016 seal ring

-

AXXON MMG18057701 APJ5018 wide mouth seal ring (2.2-3)

-

AXXON MMG18057801 APJ5007 1500 flow channel

-

AXXON MMG18057901 APJ5007-1 1500 standard flow channel assembly

-

AXXON MMG18058001 APJ5007-2 1500 standard flow channel assembly (insertion tube)

-

AXXON MMG18017801 APJI018-1 O-ring (red) (10pcs/pack)

-

AXXON MMG18018301 APJI018-2 O-ring (brown) (10pcs/pack)

-

AXXON MMG18004901 APJ1019 nozzle sleeve

-

AXXON MMG18021201 APJ1019-1 nozzle sleeve (sealed wide mouth-GW)

-

AXXON MMG18022001 APJI006-18 nozzle 30um

-

AXXON MMG18005501 APJ1006-1 nozzle 50um

-

AXXON MMG18050701 APJ1006-1-2 nozzle 50um-1.2

-

AXXON MMG18005601 APJ1006-2 nozzle 75um

-

AXXON MMG18010701 APJ1006-2-1 ceramic nozzle 75um

-

AXXON MMG18024401 APJ1006-2-2 nozzle 75um (S)

-

AXXON MMG18025801 APJ1006-2-3 nozzle 75um (C)

-

AXXON MMG18009401 APJ1006-14 Nozzle 75um-2.5

-

AXXON MMG18054001 APJ1006-14-1 Nozzle 75um-4.5 (PD)

-

AXXON MMG18014401 APJ1006-17 Nozzle 80um-4.5 Extended Nozzle

-

AXXON MMG18005701 APJ1006-3 Nozzle 100um

-

AXXON MMG18010801 APJ1006-3-1 Ceramic Nozzle 100um

-

AXXON MMG18025901 APJ1006-3-2 Nozzle 100um (C)

-

AXXON MMG18007401 APJ1006-9 Nozzle 100um-2.5

-

AXXON MMG18053301 APJ1006-9-1 Nozzle 100um-1.6

-

AXXON MMG18012201 APJ1006-15 Nozzle 100um-3.5

-

AXXON MMG18016301 APJ1006-17-1 Nozzle 100um-4.5 Extended Nozzle

-

AXXON MMG18007701 APJ1006-12 Nozzle 100um-5 (J)

-

AXXON MMG18016701 APJ1006-12-1 Nozzle 100um-5 (S)

-

AXXON MMG18049901 APJ1006-12-2 Nozzle 100um-6

-

AXXON MMG18007201 APJ1006-7 Nozzle 125um

-

AXXON MMG18010901 APJ1006-7-1 Ceramic Nozzle 125um

-

AXXON MMG18007501 APJ1006-10 Nozzle 125um-2.5

-

AXXON MMG18019501 APJ1006-10-1 Nozzle 125um-4.5

-

AXXON MMG18007301 APJ1006-8 Nozzle 150um

-

AXXON MMG18011001 APJ1006-8-1 Ceramic Nozzle 150um

-

AXXON MMG18026101 APJ1006-8-2 Nozzle 150um (C)

-

AXXON MMG18009201 APJ1006-13 Nozzle 150um-2.5

-

AXXON MMG18019601 APJ1006-13-1 Nozzle 150um-4.5

-

AXXON MMG18031101 APJ1006-13-2 Nozzle 150um-5 (thin diameter)

-

AXXON MMG18051801 APJ1006-13-3 Nozzle 150um-5

-

AXXON MMG18005801 APJ1006-4 Nozzle 200um

-

AXXON MMG18026001 APJ1006-4-1 Nozzle 200um (C)

-

AXXON MMG18022701 APJ1006-11-1 Nozzle 200um-3.5

-

AXXON MMG18029701 APJ1006-11-5 Nozzle 200um-2.5

-

AXXON MMG18007601 APJ1006-11 Nozzle 200um-5

-

AXXON MMG18029601 APJ1006-11-4 Nozzle 200um-20

-

AXXON MMG18053401 APJ1006-11-6 Nozzle 200um-7 (1)

-

AXXON MMG18053501 APJ1006-11-7 Nozzle 200um-7 (2)

-

AXXON MMG18053601 APJ1006-11-8 Nozzle 200um-7 (3)

-

AXXON MMG18053701 APJ1006-11-9 Nozzle 200um-7 (4)

-

AXXON MMG18031501 APJ1006-19 Nozzle 250um

-

AXXON MMG18005901 APJ1006-5 Nozzle 300um

-

AXXON MMG18050801 APJ1006-5-2 Nozzle 300um-3.5

-

AXXON MMG18065301 APJ1006-5-4 Nozzle 300um-4.5

-

AXXON MMG18065901 APJ1006-5-6 Nozzle 350um-3.5 (JV)

-

AXXON MMG18006001 APJ1006-6 Nozzle 400um

-

AXXON MMG18031001 APJ1006-6-1 Ceramic Nozzle 400um

-

AXXON MMG18050901 APJ1006-6-2 Nozzle 400um-3.5

-

AXXON MMG18052601 APJ1006-6-3 Nozzle 500um-3.5

-

AXXON MMG18052701 APJ1006-6-4 Nozzle 500um-3.5 (J)

-

AXXON MMG18012701 APJ1006-16 Nozzle 600um

-

AXXON MMG18052801 APJ1006-6-5 Nozzle 600um-3.5

-

AXXON MMG18052901 APJ1006-6-6 Nozzle 600um-3.5 (J)

Ⅲ、Why Choose AXXON Dispensing Valves?

-

High Precision: Exact glue control for critical applications.

-

Contactless Dispensing: No wire drawing or gold wire pressing.

-

High Stability: Consistent quality across operations.

-

Fast Speed: No Z-axis movement, boosting efficiency.

-

Wide Applications: Ideal for electronics, automotive, and more.

Ⅳ、Precision Features of AXXON Nozzles and Tappets

-

Processing Method: Custom-made per drawings or samples.

-

Aperture Accuracy: Up to 0.03mm.

-

Finish: Mirror surface Ra0.1.

-

Concentricity: 0.002mm.

-

Hardness: 85-95 HR.

-

Temperature Range: -55 to 260°C.

-

Materials: Tungsten steel, ceramics, diamond, carbide, stainless steel.

Ⅴ、Materials of AXXON Dispensing Parts

Tappets:

-

Stainless Steel: Corrosion-resistant and durable.

-

Carbide, Tungsten Steel, Diamond, Ceramics: Exceptional wear resistance.

Nozzles:

-

Stainless Steel: Ideal for viscous glues with corrosion resistance.

-

Plastic: Lightweight, cost-effective for disposable use.

-

Ceramic, Carbide, Tungsten Steel, Diamond: Superior wear resistance.

Ⅵ、AXXON Parts and Consumables

Ⅶ、Our Clients

View Client Case Studies

For inquiries or orders, call us at +86 18975335491

Ⅷ、Frequently Asked Questions

Q: What industries use AXXON dispensing parts?

A: Electronics, automotive, lighting, and manufacturing.

Q: Can I order custom parts?

A: Yes, contact us with your specifications!