Product Number:M6

Product Usage:Solder, glue, paint

Applicable Industries:SMT printers are used in the electronics manufacturing industry, mainly for circuit board assembly. They can also be used for logo and pattern printing on textiles, advertising and electronic products.

National Advisory Hotline:

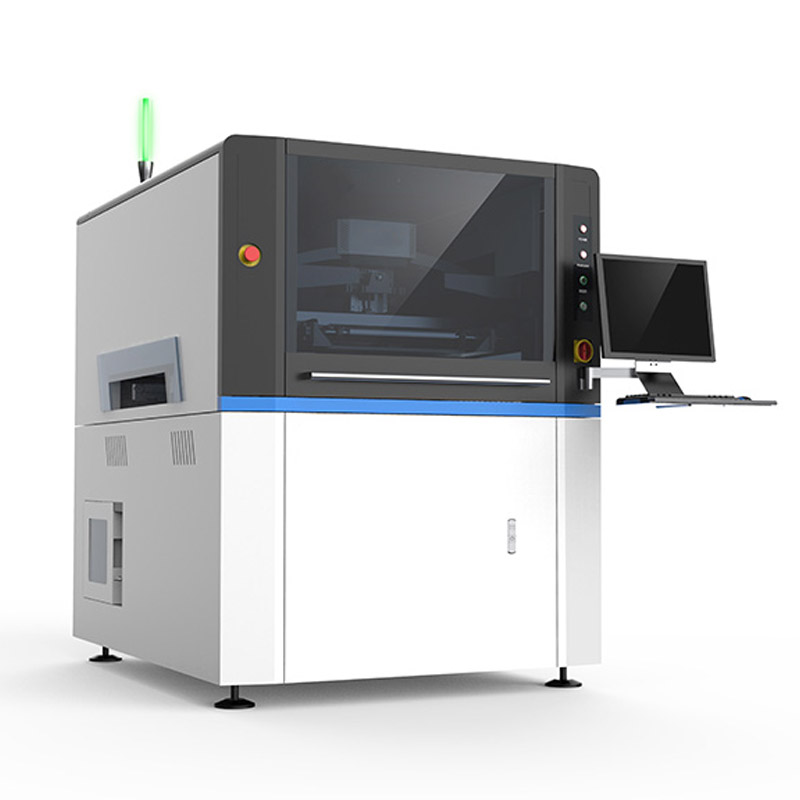

+86 18975335491The JHIMS M6 is a fully automatic visual printing machine designed for high-precision solder paste application in electronics manufacturing. Ideal for mini LED, transparent screens, servers, and high-power power supplies, the M6 delivers exceptional performance for 0201 components and 0.25 pitch applications.

| Specification | Details |

|---|---|

| Screen Frames Min Size | 520x400mm |

| Screen Frames Max Size | 850x750mm |

| Screen Frames Thickness | 20-40mm |

| Stencil Position Mode | Automatic Y-direction positioning |

| PCB Min Size | 50x50mm |

| PCB Max Size | 650x340mm |

| PCB Thickness | 0.4~6mm |

| PCB Warpage | <1% |

| PCB Board Edge Clearance | 2.5mm |

| Board Height | 25mm |

| Transport Height | 900 ± 40mm |

| Transport Direction | Left-Right; Right-Left; In and out the same |

| Transport Speed | Segment control, 1500mm/s (Max) |

| Transport Mode | One section transportation track |

| PCB Support System | Magnetic Pin, Support Block, Manual Up-down table |

| Maximum PCB Board Weight | 6kg |

| Printing Speed | 10-200mm/sec |

| Printing Pressure | 0.5-25kg |

| Printing Mode | Single or double squeegee printing |

| Release Distance | 0-20mm |

| Release Speed | 0-20mm/sec |

| Snap-Mode | Three stage demolding |

| Squeegee Type | Rubber squeegee/Steel squeegee (angle 60° /55° /45° Optional) |

| Repeat Position Accuracy | ±0.01 mm |

| Printing Accuracy | ± 0.025mm |

| Cycle Time (Excluding Cleaning) | 7s |

| Cycle Time (Including Cleaning) | 15s |

| Changeover Time | 5Min |

| Cleaning Method | Spraying cleaning system, Dry wipe, wet wipe, vacuum three modes |

| Cleaning Stroke | 3~6 Automatic generation |

| Cleaning Position | Post cleaning |

| Cleaning Speed | 10~200mm/sec |

| Cleaning Fluid Consumption | Auto & Manually adjustable |

| Cleaning Paper Consumption | Auto & Manually adjustable |

| CCD FOV | 10*8mm |

| Camera Type | 1.30 megapixel digital camera |

| Camera System | Geometric matching, up and down imaging vision |

| Camera Cycle Time | 150ms |

| Fiducial Mark Types | Standard Fiducial Mark Shape: square, circle, triangle, diamond shaped, ten cross, welding, opening, Pad, profile hole |

| Mark size | 0.1-6mm |

| Stay Away Number | Max: 1pcs |

| Mark Number | Max: 4pcs |

| 2D Detection | Detect low tin/missing print/continuous tin |

| Safely Control | Door open to stop, abnormal alarm |

| Smart UI | Brand new interface, shortcut key operation |

| Permission Setting | It can be freely set, and the authority division of operators, technicians and engineers can be set |

| Standard MES System | Customized output of Industry 4.0 solutions, can record SOP and equipment open data, and upload |

| Temperature and Humidity Detection (option) | Real time display of indoor temperature and humidity of equipment |

| SPI Connection (option) | Automatic compensation for offset and detection of less tin, Automatic cleaning of steel mesh |

| Automatic Tinning (option) | Filling 500g universal automatic tinning (single can) |

| Steel Mesh Detection System (option) | Real detection of steel mesh blockage, automatic feedback alarm |

| Automatic Dispensing System (option) | Can automatically apply red glue and solder paste. |

| In Series | Two machines are printed in tandem to increase productivity |

| Air Required | 4.5〜6Kg/cm² |

| Air Consumption | 5L/min |

| Working Temperature | -20°C~45°C |

| Working Environment Humidity | 30%-60% |

| Power Input | AC: 220 ±10%, 50/60HZ 2.5KW |

| Control Method | PC Control |

| Machine Weight | Approx: 1100Kg |

| Machine Dimensions | 1330(L) x 1370(W) x 1500(H)mm |

"The JHIMS M6 has revolutionized our PCB assembly process. Its precision and automation capabilities are unmatched." - John Doe

"Reliable product quality, timely service, is a trustworthy business." - Mona

"Great value for money, improved our production efficiency significantly." - Sarah Lee

Compared to other SMT solder paste printers, the JHIMS M6 offers superior precision and automation at a competitive price point. Its ability to handle 0201 components and mini LED applications sets it apart from many alternatives.

For more information or to request a quote, please contact us or explore our SMT Printers category.